- Home

- >

- Shot peening

What is shot peening ?

What is shot peening – ultrasonic shot peening ?

Our shot peening process is used to improve:

- Fatigue resistance

- Resistance to stress corrosion cracking and contact fatigue

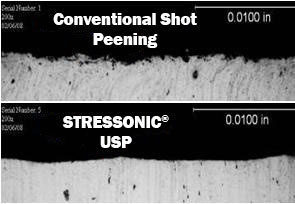

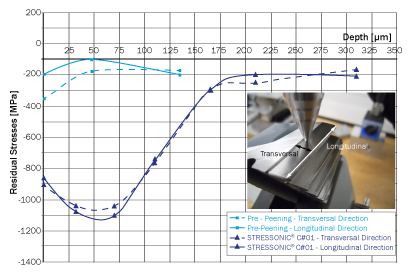

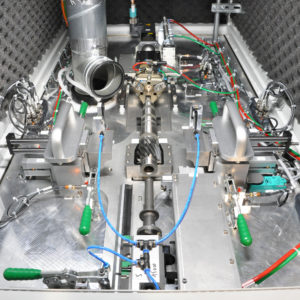

This surface impact treatment solution consists in bombarding the specific area to be peened with small projectiles (= media). This action induces residual compressive stress on the surface, which delays the appearance of cracks, and improves the lifetime of the part. This is a cold working and work hardening process.